Belt scales

Belt scales

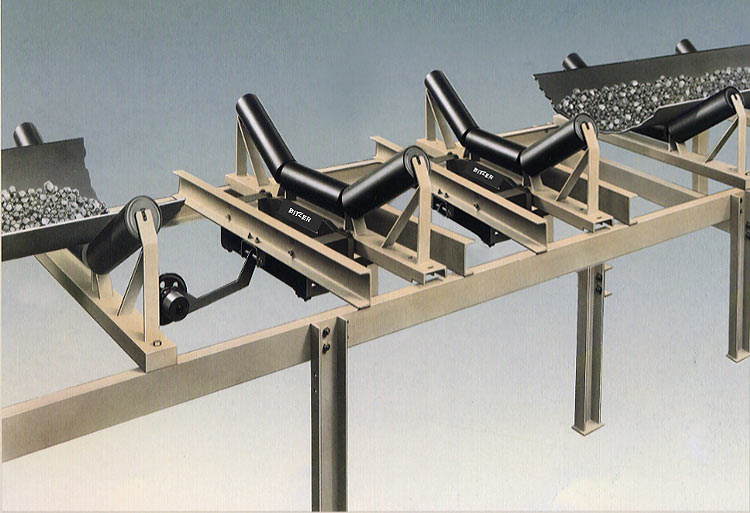

Belt scales are used for dynamic weight determination and can be found in many industry branches. Chemical companies, food and feed manufacturers, building materials companies, recycling companies and others use belt weighers for internal checkweighing, loading, batching, and mixing of a wide variety of bulk materials.

Belt scales consist of a weighing frame and load cells and can be installed in both new and existing conveyor belts. They are available as single-roller and multi-roller belt weighers. Thanks to the intelligent design, the belt weigher can be easily integrated into conveyor belts. The bulk material running over the belt generates pressure on the rollers underneath. At the corresponding measuring station, this pressure is recorded by the weighing frame with load cells. By default, capacities between 45 t/h and 700 t/h can be precisely recorded.

Stainless steel load cells

Maintenance-free execution

Conveying capacity

between 45 t/h and 700 t/h

User-friendly

Calibratable (as an option)

Applicable in ATEX zones

The accuracy of belt scales depends mainly on external influencing factors. For example, the troughing of the belt or weather influences (elongation of the belt in the case of strong temperature changes) can affect the accuracy. In general, the error limit is between 0.50 % and 2.00 %, for calibrated belt scales between 0.50 % and 1.00 %.

Do you already have an existing system?

We will be happy to determine during an on-site survey which possible interfering factors can affect the measurement accuracy and provide advices for improvement.

Download our leaflet of belt scales now:

Efficient data acquisition and accessories for belt scales

The measured weight values are reliably recorded via weighing electronics. These devices include at least three capacity counters (t/h), e.g. for daily quantity, monthly quantity and total quantity, as well as numerous adjustable parameters for correcting the conveyor belt properties. If the belt scale is to be designed as a loading scale, a setpoint can be specified via the weighing electronics. When this setpoint is reached, loading stops automatically. Furthermore, the scale can be used as a weighfeeder by means of special software.

The scale is optionally also suitable for use in ATEX zones and can also be designed in stainless steel V2A / V4A. Common interfaces via Profibus DP, Profinet, Ethernet and analog outputs can be integrated, so that the connection to an existing process control system is possible without any problems. Due to the connectivity of our BITZER Web Software, the belt scale can also be integrated into a yard logistics system.

Depending on your individual requirements, you can optionally purchase speed measuring devices and external pulse counters as accessories for your belt weigher.

We will be happy to advise you on the right design for your new belt weigher.

Weighfeeder

A special type of belt weigher is the weighfeeder. The measuring principle of a weighfeeder corresponds to the principle of a belt weigher (weight and speed measurement). In addition to the actual measuring program, control parameters are available which enable a constantly specified continuous material flow. The control can be carried out via the belt speed or via the control of feeding elements. The control program of the weighfeeder compares the actual feed rate with the set target feed rate and controls the feeding element. In practice, such weighfeeders are used, for example, for recipe-controlled dosing of components from several silo cells.

Any questions?

Our sales team is looking forward to your call or email.

Our sales team:

Tel.: +49 (0) 5121 / 7828 – 51

Fax.: +49 (0) 5121 / 7828 – 78

Email: marketing@bitzer-waage.de